BRAM-COR’s experience and passion for the processing of stainless steel ensures quality and professionalism even for the smallest details

Energy saving concerns, sanitary quality and certifications for all materials and components and long-term reliability are imperative attributes for all our equipment.

Each and every BRAM-COR plant and production line is designed and produced rigorously following cGMP procedures. AISI 316L stainless steel pipes and AISI 304 stainless steel frames are welded by qualified welders following BRAM-COR Sanitary Piping procedures. Our extended knowledge of raw materials and our strict manufacturing and assembly guidelines, enable BRAM-COR to supervise and qualify every aspect of the plants. Non-destructive tests are performed throughout the entire construction process.

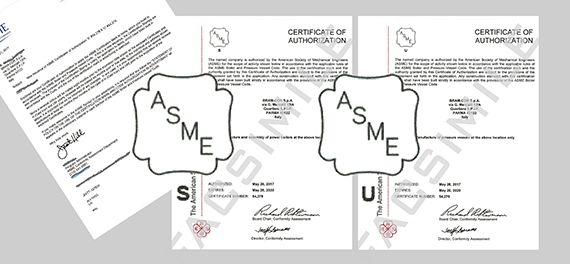

BRAM-COR products’ quality is ensured by our compliance with the ISO 9001:2015. Planning, monitoring, testing, identifying and recording every step throughout the life of our plants and products constitutes the baseline of our work, from system design to system validation. Continuous improvement is pursued through a scrupulous and dynamic assessment of any non-conformity, owning to the steady revision of our working procedures.

For this very reason, each BRAM-COR plant is unique and retains a set of peculiar characteristics. BRAM-COR aims to provide the highest pharmaceutical quality, a convenient quality/price ratio and wide customisation for every single plant. BRAM-COR additionally ensures a qualified and professional customer support throughout the entire life cycle of our pharmaceutical plants, on account of our rigorous teamwork etiquette.

Each component is identified by a unique TAG, engraved on metal plate, for total traceability in the relevant technical documentation. Functional testing is ensured by automation experts, with special care for monitoring of critical parameters. Documentation, inspection and field testing are included in our project management.